Our Products Line

TechnaFeeder

Technavia product line has 4 & 2 spindle feeder known as Technafeeder mainly suitable for feeding light weight component for painting like lense, bezels and other plastic components. Technafeeder consists of two servo motors used for rotating arm and fixture station respectively. The fixture station can be positioned in desired angle for making more access to the robot irrespective of the components profile. The servo motors are placed in a pressurized chamber making it explosion proof and reliable in using in hazardous area.

Key features:

- It is compact and two axes rotary feeder.

- Available in 3 Table pitch – 1400, 1600, 1800 mm.

- Saving the space by mounting the Robot on wall above the Technafeeder.

- Saving energy by driving 5 axes with only two servo motors.(one axis for arm rotation & four axes for table rotation in case of 4 Arm type).

- Maintenance-free AC Servo motor.

- Higher productivity by painting multiple work pieces at one time.

Optimal spray angles for different sizes and shapes of work pieces by coordinating indexing and movements of a robot. - Easy teaching of spindle rotations and quick reset to home position by using the endless rotary function of the servo motor.

- Extremely smooth running through gear type & belt type transmission.

Vertax & Horax

Technavia has developed two reciprocator models VERTAX and HORAX which are basically used in vertical and horizontal method of painting. Both models have three variants categorised by the reciprocator’s stroke length.

The reciprocator can be efficiently used in liquid as well as powder coating line and can be equipped with any type of applicator like conventional gun, electrostatic gun, Bell….etc.

We also have a reciprocator model with disc applicator, which is best suited for omega shaped booth.

Key features:

- Long-stroke and short-stroke operation.

- High loading capacity and stability.

- Slim column design allows space-saving arrangement of the guns.

- Extremely smooth running through toothed belt transmission.

- Maintenance free AC Servo motor.

- Single-axis motion with variable stokes available.

- Free axis programming via HMI Control Unit.

- 100 storable programs for Different work piece.

- The Reciprocator is equipped with variable speed control.

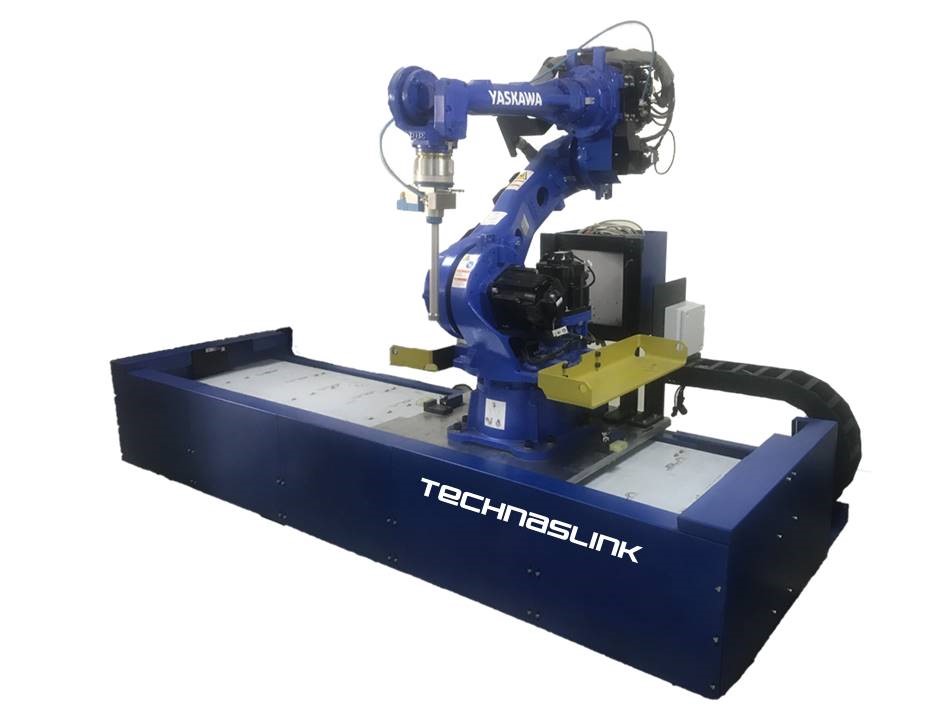

Technaslink

Technavia has single axis servo slider for robot travelling and for enhancing the accessibility of the robot. Robot movement can be synchronised with the slider hence giving more access to robot for coverage while teaching on

Varying components.

Key features:

- Best in class path and motion accuracy.

- Compact design and fits for any make robot model.

- Equipped with highest reliable components.

- Comes in wide range of options suiting different configuration.

- Used in wide range of application by enhancing the accessibility of the robotic arm.

- Easy to maintain and high in reliability.

SCADA System - Technaview

Technavia has its SCADA (Supervisory Control and Data Acquisition) which is a control system architecture that uses computers, networked data communication and graphical user interfaces for high-level process supervisory management. SCADA uses PLC for logically controlling the process of devices used in the system and to demonstrate on the screen.

SCADA enhances the productivity by making it easy to monitor the various parameters in the painting process. The SCADA system provided by us is as per the industry 4.0 standard.

Bell Cleaner

Technavia has developed Bell cleaner system for avoiding manual cleaning of bell shroud and thus risking it to get damage. The bell cleaner run through a series of operation where first solvent is injected with a high speed rotary mechanism on the shroud and then the same process with air is applied. This process with solvent and air is consecutively applied as per the set time. The bell cleaner comes with wall and floor mounting arrangement and could be placed as per the requirement.

Key features:- Compact and sleek design

- Full stainless steel body

- Compatible with different make bells

- Easy in maintenance and cleaning

- Provision of mounting on floor and wall

Pigging system

Pigging system is yet another development jointly done by Technavia and POMA systems. The use of pigging technology optimizes profitability in paint shops - through short colour change times and material recovery. With pigging system the valuable paints and hardeners are feed back to the supply units in optimum purity, or remove the excess line content quickly and without residue from the line systems with minimal loss.

Key features:- Pigging system recovers paint and hardener with optimal purity

- Shortens paint change time

- Saves the usage of solvent for cleaning and flushing purpose

- Eco friendly by preventing dumping of hazardous chemicals in environment

- Easy to customised as per the system requirement

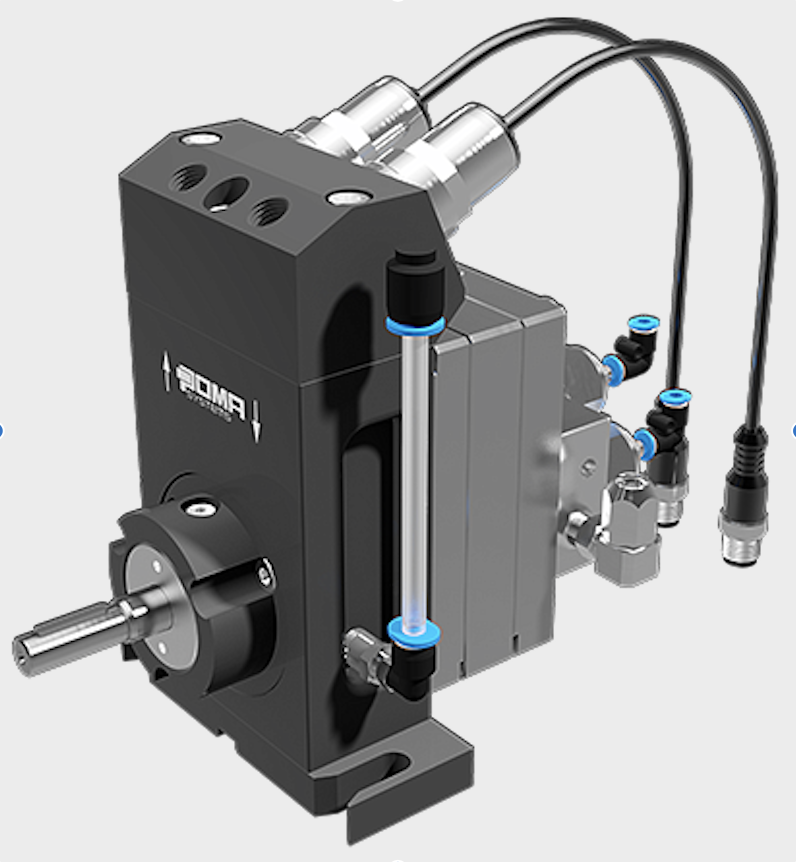

Dosing unit (FGP)

FGP(flushable gear pump) is our compact design dosing unit, which shaped with the joint effort of Technavia and POMA systems. Use of FGP provides accuracy in paint dosing and by mounting it on the robot arm it shortens the hose length from dosing pump to atomizer thus reduces paint loss while colour changing.

Key features:- Large band width of adjusting the paint volume by controlling the servo speed.

- Reduces contamination of dead volume of paint in the component.

- Most efficient in colour changing time.

- Quick in purging and reduces purging agent consumption.

- Consistently high metering accuracy through automatic pressure adjustment

- Key operating components made of stainless steel

- Maintenance-free to a large extent

- Compact design and optimised for mounting on robot arm.

- High quality components give it an extended life.

- Explosion proof servo motor provided for operating in a fire hazardous environment

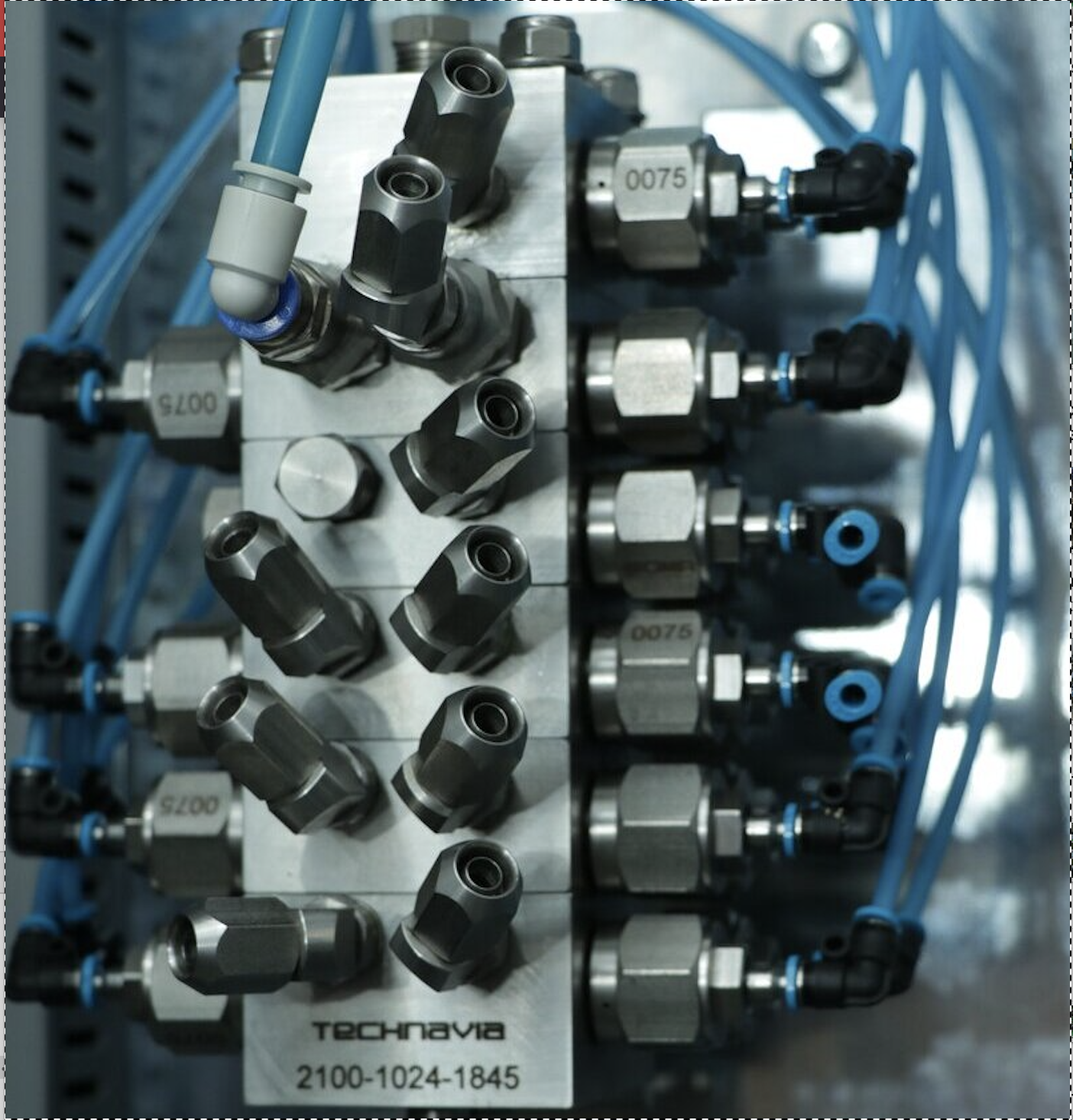

Colour Changing Unit

Colour changing unit is developed with a technical collaboration of Technavia with a renowned German company POMA Systems. Our product range includes single colour changers, double colour changers, star colour changers and inline colour changers. The colour changing unit comes in modular form and can be changed as per the number of colours added. The paint connectors are available in variety of hose size.

Key features:- Optimised for quick colour changing

- Almost all components are made of stainless steel

- Précised valve boring ensures valves are long lasting & reliable

- Easily customised to suit any special requirement

- Modular valve arrangement makes installation easy